-

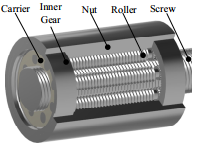

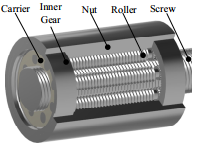

Structural design for planetary roller screw mechanism based on the developed contact modelling(22年基于接触建模的行星滚滚柱丝杠结构设计)

The structural design of planetary roller screw mechanism (PRSM) with lower contact stress is beneficial to delay

the fatigue failure and prolong the service life. However, few studies focused on this field and a reasonable

contact model is therefore required due to its complexity structure. In this paper, a developed contact model is

established for PRSM, and a process-based parameterization method is proposed to precisely calculate the

contact characteristics along with the change of parameters. Based on the in-depth study of the parameter

sensitivities of contact characteristics, the structure design to reduce contact stress for PRSM is realized through

the multi-objective optimization under the proposed geometric constraints. The validity of this model is well

verified by finite element method.

阅读:

阅读:

2022-04-10

2022-04-10

-

.png)

Fatigue lifespan of a planetary roller-screw mechanism(22年行星滚柱丝杠机构的疲劳寿命)

Electro-mechanical actuators including planetary roller screw (PRS) support cyclic loads in

aeronautical conditions. PRS multiple thread contacts between screw, rollers and nut allow the

mechanism to support large loads. However, aeronautical accreditation requires fine prediction

of fatigue lifespan. In this paper, a fatigue design strategy for PRS mechanisms is proposed

combining Hertz contact model and a multi-axial fatigue criterion. The method is applied on

two examples, one standard and one inverted PRS.

The lifespan of PRS mechanism depends on maximal Dang Van stress. The Hertz sliding angle (Hertz contact main direction/sliding velocity) was introduced to analyze PRS performances.

For both examples, the maximum stress at thread contact were located in bulk material but not

at the surface. Dang Van stress mainly depended on curvature ratio, Hertz sliding angle and

loads. Based on this analysis, Dang Van criterion was implemented to derive the loading domain

of infinite lifespan of the mechanism. Critical contact was not always on the roller-screw side.

阅读:

阅读:

2022-01-16

2022-01-16

-

凸凹接触式行星滚柱丝杠的啮合承载特性(Meshing and bearing characteristics of convex-concave contact planetary roller screw mechanism)

摘 要: 为提高行星滚柱丝杠的承载能力,分析优化行星滚柱丝杠的螺纹牙型,提出一种基于凸凹接触的啮合方式。 设计凹

圆弧的丝杠和螺母牙型轮廓,基于空间啮合理论推导螺纹曲面方程、空间啮合方程,并基于赫兹接触理论和变形协调方程建

立负载分布模型;采用数值计算的方法对啮合点位置、轴向间隙和接触应力进行求解,系统揭示了牙侧角、螺距等参数对啮合

点位置、轴向间隙和负载分布的影响规律,并对比分析标准式和凸凹式行星滚柱丝杠的接触应力。 结果表明:牙侧角对轴向

间隙的影响最大,丝杠和螺母的凹圆弧半径变化对接触点位置和轴向间隙几乎没有影响,但对承载能力影响十分明显;与标

准式相比,凸凹接触式行星滚柱丝杠的承载能力有较大的提高,丝杠和螺母凹圆弧半径越小承载能力提高越明显。 本研究为

研制高承载、高使用寿命的行星滚柱丝杠提供了优化设计和分析的依据。

阅读:

阅读:

2022-01-15

2022-01-15

-

Investigation on the mechanical behavior of planetary roller screw with the effects of external loads and machining errors

Abstract: Planetary roller screws are the key mechanical components used in linear motion and could be subjected to radial and axial loads in application. However, the effect of radial force on load distribution and fatigue life has not been considered in previous studies...

阅读:

阅读:

2021-06-24

2021-06-24

-

.jpg)

Analysis of transient mixed elastohydrodynamic lubrication in planetary roller screw mechanism(21年行星滚柱丝杠瞬态混合弹流润滑分析)

Previous lubrication studies for planetary roller screw (PRSM) are mainly concentrated on steady-state condition

without the consideration of entrainment angle. However, PRSM always operates in transient situations with

frequent startup and shutdown process. In this paper, uneven friction distribution, the influence of helix angle on

lubricating properties and transient behavior in the roller-screw interface are analyzed comprehensively based

on transient mixed-EHL model, which considers real three-dimensional (3D) machined roughness and arbitrary

entrainment velocity. The results show that smaller helix angle is beneficial to improve the lubrication performance. Increasing the rotating speed and declining axial load can moderate the uneven friction distribution.

Besides, a relatively large angular acceleration may enlarge the film thickness and reduce the friction at the shut

down status. The numerical simulation model can be utilized as a design optimization tool for the PRSM.

阅读:

阅读:

2021-06-17

2021-06-17

-

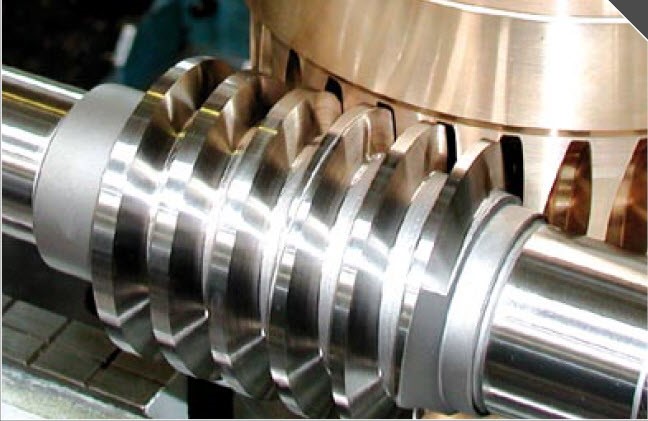

精密蜗杆传动副磨损量补偿及侧隙调控方法

蜗杆传动是机械传动的一种主要形式,具有传动比范围宽、结构紧凑、体积小、运动平稳、噪声低等优点,除被广泛应用于动力传动外,也是机床及精密仪器精密圆分度机构的首选部件...

阅读:

阅读:

2021-05-25

2021-05-25

-

蜗杆传动的发展及其分类

摘要:回顾了蜗杆传动的发展历程,并阐述了各种蜗杆传动的优缺点。从蜗杆传动中的首创体外形、齿部位置及啮合区域、首创面齿廓三个方面出发对蜗杆传动进行分类,以元素周期表为原型得出蜗杆传动系统分类表,表中各类型、各系列及各形式之间在几何结构和传动性能上存在一定的普遍性和规律性...

阅读:

阅读:

2021-05-25

2021-05-25

-

差动式行星滚柱丝杠承载特性分析

摘要:基于空间啮合理论与赫兹接触理论展开差动式行星滚柱丝杠承载特性分析,综合考虑由滚柱与丝杆初始啮合点偏置引起的接触点位置变化对承载特性的影响,建立差动式行星滚柱丝杠空间啮合...

阅读:

阅读:

2021-05-25

2021-05-25

-

Multi-objective optimization of planetary roller screw mechanism based on improved mathematical modelling(21年行星滚柱丝杠基于改进的数学建模的多目标优化)

The optimization of obtaining the most uniform load distribution is important for the load carrying capacity

design of the planetary roller screw mechanism (PRSM). However, the stiffness matrix of PRSM in traditional

method based on the relationship between load and deformation of the thread may be destroyed when threads

are no longer in contact due to machining errors, which would bring convergence problem in optimization

process. In this paper, the mathematical model is firstly established to overcome the above drawbacks by proposing an improved iterative algorithm. Then, the multi-objective optimization is conducted to search the best

designed pitches for the most uniform load distribution on both the screw-roller and nut-roller interfaces, and

results are verified by the finite element method.

阅读:

阅读:

2021-04-15

2021-04-15

-

A Multiscale Accuracy Degradation Prediction Method of Planetary Roller Screw Mechanism Based on Fractal Theory Considering Thread Surface Roughness(21年一种行星滚柱丝杠多维度精度下降预测方法)

Abstract: The wear problems are vital to the planetary roller screw mechanism (PRSM) as they

have a great influence on transmission accuracy, working efficiency, and service life. However,

the wear characteristics of the PRSM have been rarely investigated in the past. In this paper,

a multiscale adhesive wear model is established by incorporating the effective wear coefficient and

considering the thread surface roughness. The variation of surface roughness is characterized by

the two-dimension Majumdar–Bhushan (MB) function. The multi-asperity contact regimes are used

to estimate microcontact mechanics of the rough interface. Moreover, the influences of surface

roughness, material properties, and working conditions on the wear depth and precision loss of the

PRSM are studied in detail. The results reveal that as the surface roughness increases, the total actual

contact area, wear depth, and precision loss rate rise. In addition, the adhesive wear increases with

the growth of the axial load, and decreases with the increase in the material hardness and material

elastic modulus ratio to a certain extent. The investigation opens up a theoretical methodology to

predict the wear volume and precision loss with regard to thread surface roughness, which lays the

foundation for the design, manufacturing, and application of the PRSM.

阅读:

阅读:

2021-05-23

2021-05-23

-

.jpg)

Research on Fractal Model of Load Distribution and Axial Stiffness of Planetary Roller Screw Mechanism Considering Surface Roughness and Friction Factor(22年载荷分布和轴向刚度的分形模型研究)

The effects of surface roughness and material properties of the planetary

roller screw mechanism (PRSM) on the axial stiffness and load distribution

are rarely studied. In this paper, the load distribution model is presented by

incorporating into friction factor and surface microtopography. The

microcontact model is built by considering elastic and plastic regimes to

calculate the total actual contact area. Moreover, the load distribution model is

modified by introducing surface microcontact coefficient. Then, the influences

of the nut position, fractal dimension, fractal roughness, friction factor, axial

load, and material yield strength on the axial stiffness and load distribution

are studied in detail. The numerical results show that the axial stiffness rises

with the increment of the nut position, axial load, fractal dimension, and yield

strength, and reduces with the fractal roughness and friction factor

increasing. In addition, the uniformity of the load distribution increases with

the increment of the fractal roughness, and drops with the increase of the

fractal dimension and material yield strength. This investigation lays the

foundation for the design, manufacturing, and use of the PRSM.

阅读:

阅读:

2021-03-09

2021-03-09

-

.jpg)

Wear Behavior of Martensitic Stainless Steel in Rolling-Sliding Contact for Planetary Roller Screw Mechanism: Study of the WC/C Solution(16年马氏体不锈钢在行星滚柱丝杠滚动滑动接触中的磨损行为)

The planetary roller screw mechanism is used in the aeronautics industry for electro-mechanical actuators

application. It transforms a rotational movement into a translation movement, and it is designed for heavy

loads. The main components are made of martensitic stainless steel, and lubricated with grease. Like most

usual rolling mechanisms, smearing and jamming can occur before the theoretical fatigue lifetime, especially

in poor lubrication conditions. The actuated load is carried by small contacts between the threads of the screw,

the rollers and the nut. The static single contact can be described as an ellipsoid on flat contact with high

contact pressure (3-4 GPa). The motion consists of rolling with spin associated with side slip up to 10%. The

aim of our study is to investigate the wear behavior of the WC/C coated contact for different operating and

design parameters such as load, speed and slip ratio. The contact is simulated by a free rolling roller loaded on

a rotating disk. A specific apparatus is used to create a contact with a side slip component, i.e. perpendicular

to the rolling direction. The wheel rolling speed and the tangential force generated by the slip ratio are

measured. The wear behavior of a WC/C carbon-based composite coating is investigated. It reveals

progressive wear and cracking in the rolling direction, i. e. perpendicular to the sliding direction. A wear map

has been drawn to establish the damage mode depending on the contact conditions.

阅读:

阅读:

2016-11-02

2016-11-02

F58712BEE7444EC3BE13CD344F298ADD.jpg)

阅读:

阅读:

2022-04-10

2022-04-10

.png)

阅读:

阅读:

2022-01-16

2022-01-16

.jpg)

阅读:

阅读:

2022-01-15

2022-01-15

9D22C468462D42D89B134C12F59C6E0E.png)

阅读:

阅读:

2021-06-24

2021-06-24

.jpg)

阅读:

阅读:

2021-06-17

2021-06-17

阅读:

阅读:

2021-05-25

2021-05-25

阅读:

阅读:

2021-05-25

2021-05-25

.png)

阅读:

阅读:

2021-05-25

2021-05-25

.jpg)

阅读:

阅读:

2021-04-15

2021-04-15

阅读:

阅读:

2021-05-23

2021-05-23

.jpg)

阅读:

阅读:

2021-03-09

2021-03-09

.jpg)

阅读:

阅读:

2016-11-02

2016-11-02